Why is endotoxin testing important in the pharmaceutical industry?

Endotoxin testing is crucial in the pharmaceutical industry for two main reasons. Firstly, it ensures patient safety. When endotoxins enter the body, they can trigger severe immune responses and inflammatory reactions, leading to various health complications. By conducting rigorous endotoxin testing, pharmaceutical manufacturers can identify and eliminate endotoxin contamination, thereby safeguarding patient safety.

What role does regulatory compliance play in endotoxin testing?

Regulatory compliance is another crucial aspect of endotoxin testing in the pharmaceutical industry. Regulatory authorities, such as the United States Pharmacopeia (USP) and the European Pharmacopoeia (EP), require endotoxin testing as a mandatory quality control measure for pharmaceutical products. Compliance with these regulatory standards is essential for obtaining product approvals and maintaining market credibility. USP Chapter 85 Bacterial Endotoxins Test specifically outlines comprehensive guidelines for endotoxin testing in the United States, establishing maximum allowable endotoxin levels for different types of pharmaceutical products to protect patients from potential risks.

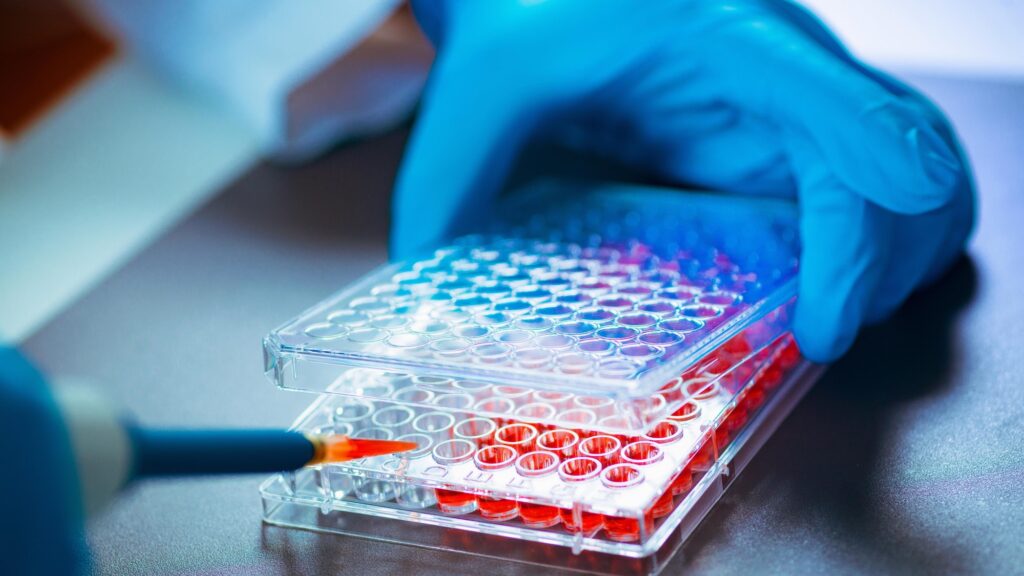

What test methods can be used to detect endotoxin?

Several test methods are available to detect and quantify endotoxin levels in pharmaceutical products. The most commonly used method is the Limulus Amoebocyte Lysate (LAL) test. There are three types of LAL tests: gel-clot, turbidimetric, and chromogenic. The gel-clot method is the traditional approach where the formation of a gel-like clot indicates the presence of endotoxins. The turbidimetric method measures the change in turbidity caused by the reaction between endotoxins and LAL reagents. The chromogenic method uses a color change reaction due to the enzymatic activity of the LAL reagents in the presence of endotoxins. The LAL is a highly sensitive enzymatic test which is specific to endotoxins and is widely accepted in the pharmaceutical industry.

What to do when my samples exceed endotoxin limits?

If endotoxin levels in your product exceed the acceptable limits, take immediate corrective actions. Investigate the source of contamination and implement necessary measures to prevent future occurrences. This may involve adjusting manufacturing processes, improving cleaning and sterilization procedures, or reviewing the quality control protocols.

In conclusion, endotoxin testing plays a critical role in ensuring the safety and quality of pharmaceutical products. It protects patients from the harmful effects of endotoxins and ensures compliance with regulatory standards, such as USP Chapter 85. By conducting thorough endotoxin testing, pharmaceutical manufacturers can confidently deliver safe and effective products to patients while upholding industry best practices.